BOOK A FREE TRIAL

Revolutionize Maintenance

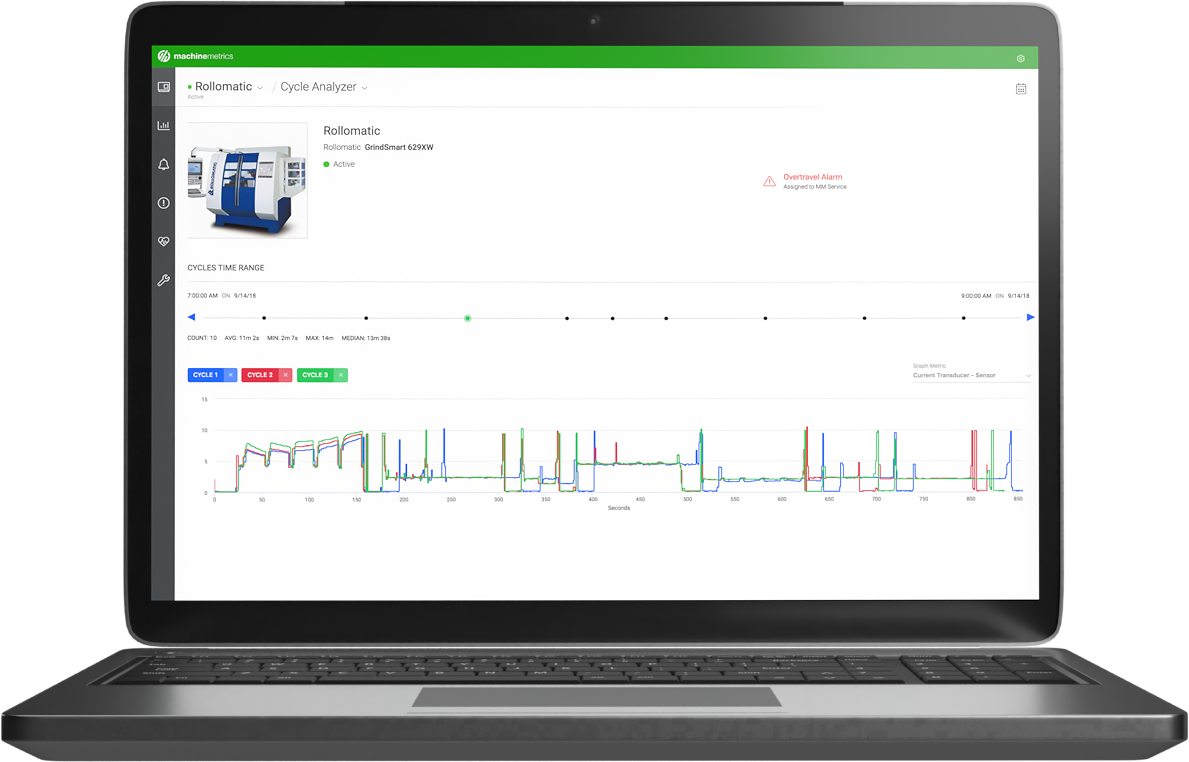

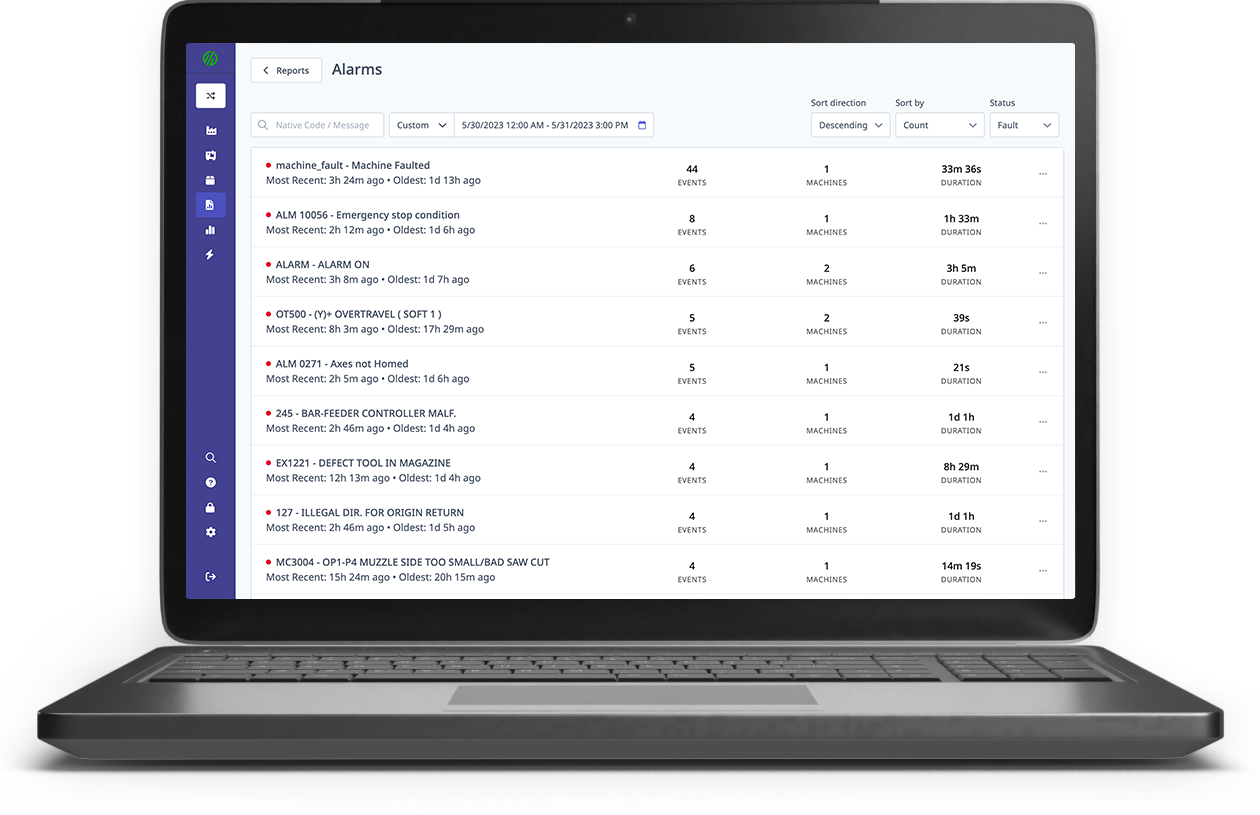

Leverage Machine Data

Reliance on calendar-based preventive maintenance plans proves inefficient and frequently results in either excessive, costly maintenance or insufficient maintenance that leads to machine failures and downtime.

Industrial IoT Platform for Machines

Mike Tamasi, President of AccuRounds

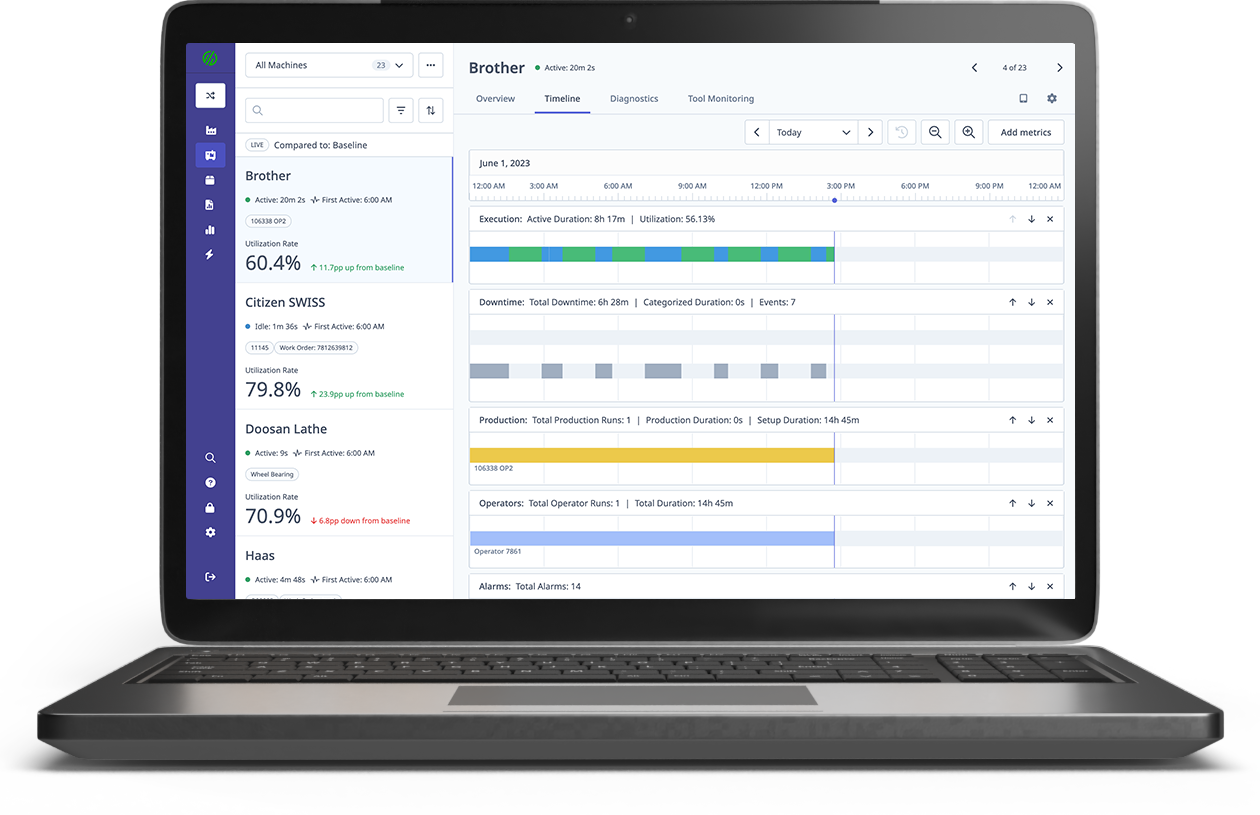

After quickly connecting twenty-three machines, AccuRounds was immediately driving process improvements with MachinoX Pro. The numbers speak for themselves.

Want to see MachinoX Pro in action first? BOOK A FREE TRIAL