BOOK A FREE TRIAL

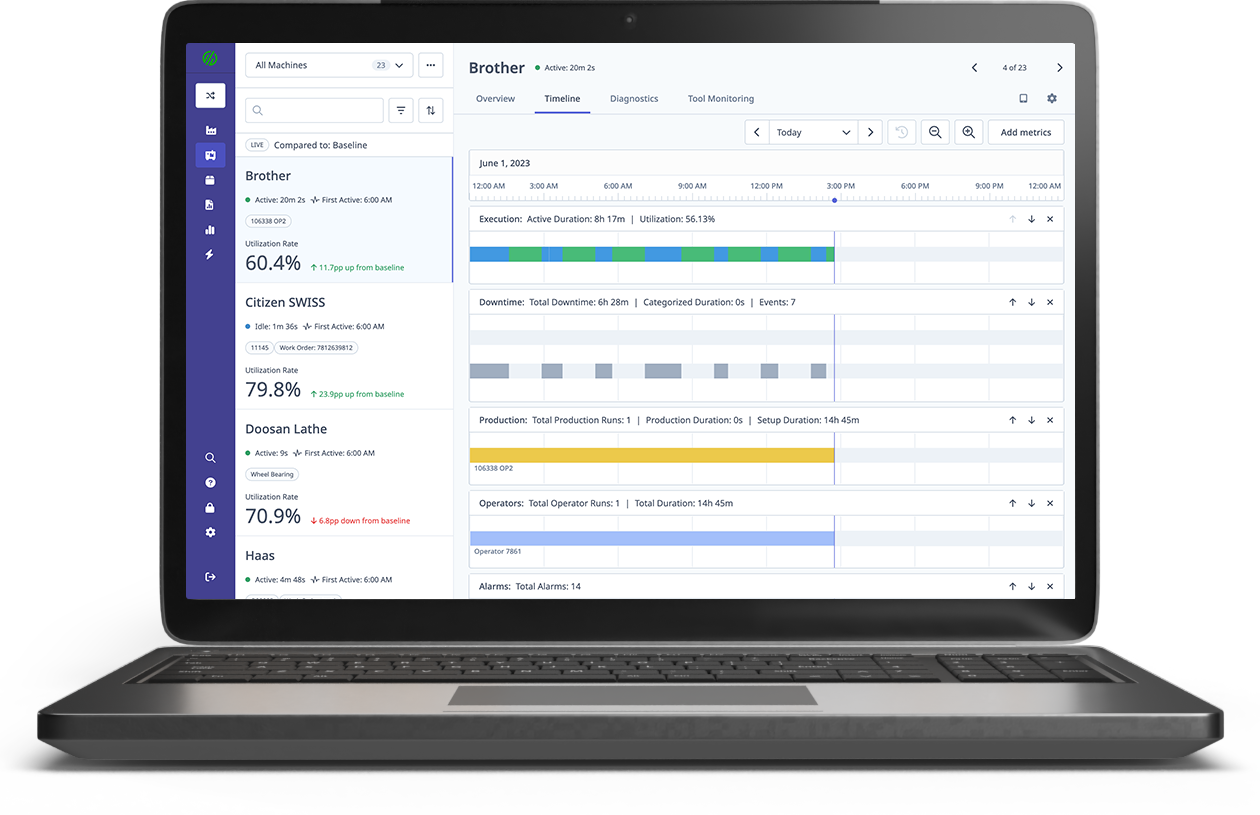

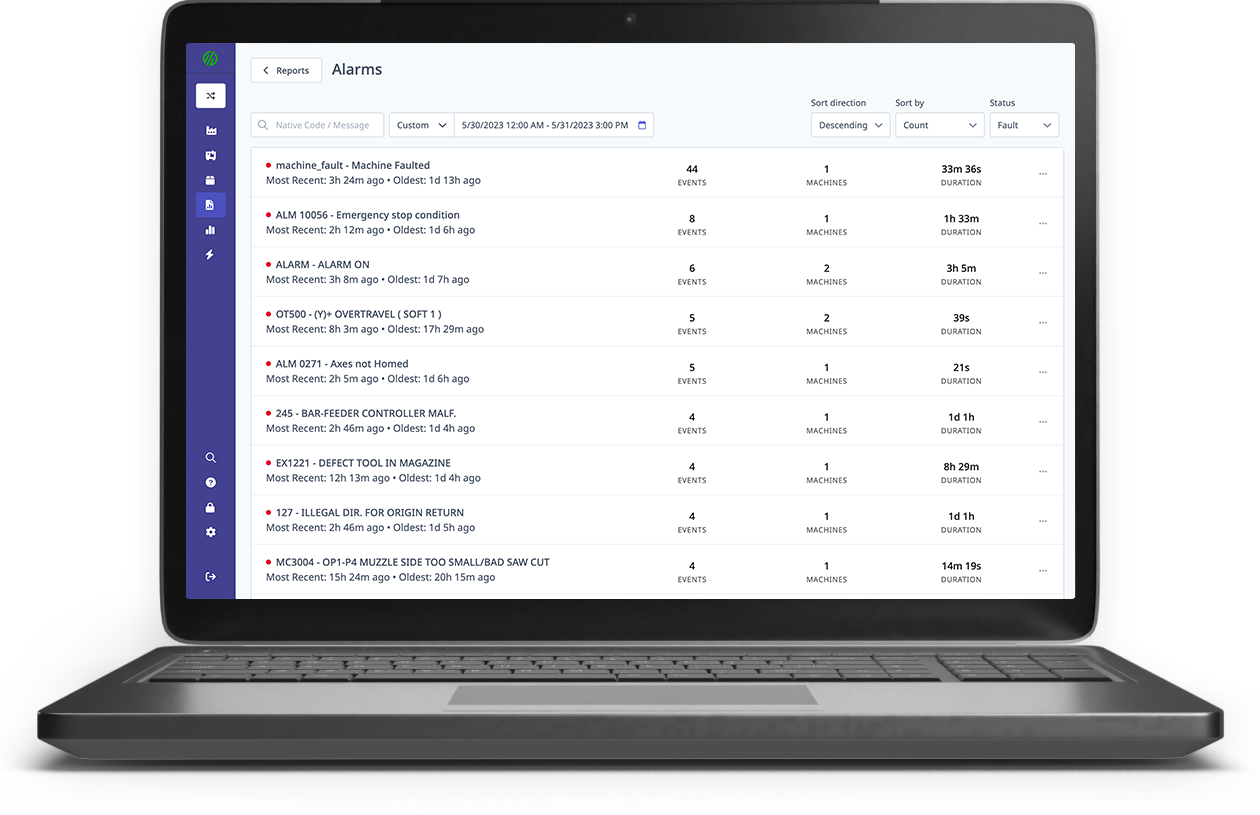

Industrial IoT Platform for Machines

Advanced Service Capabilities

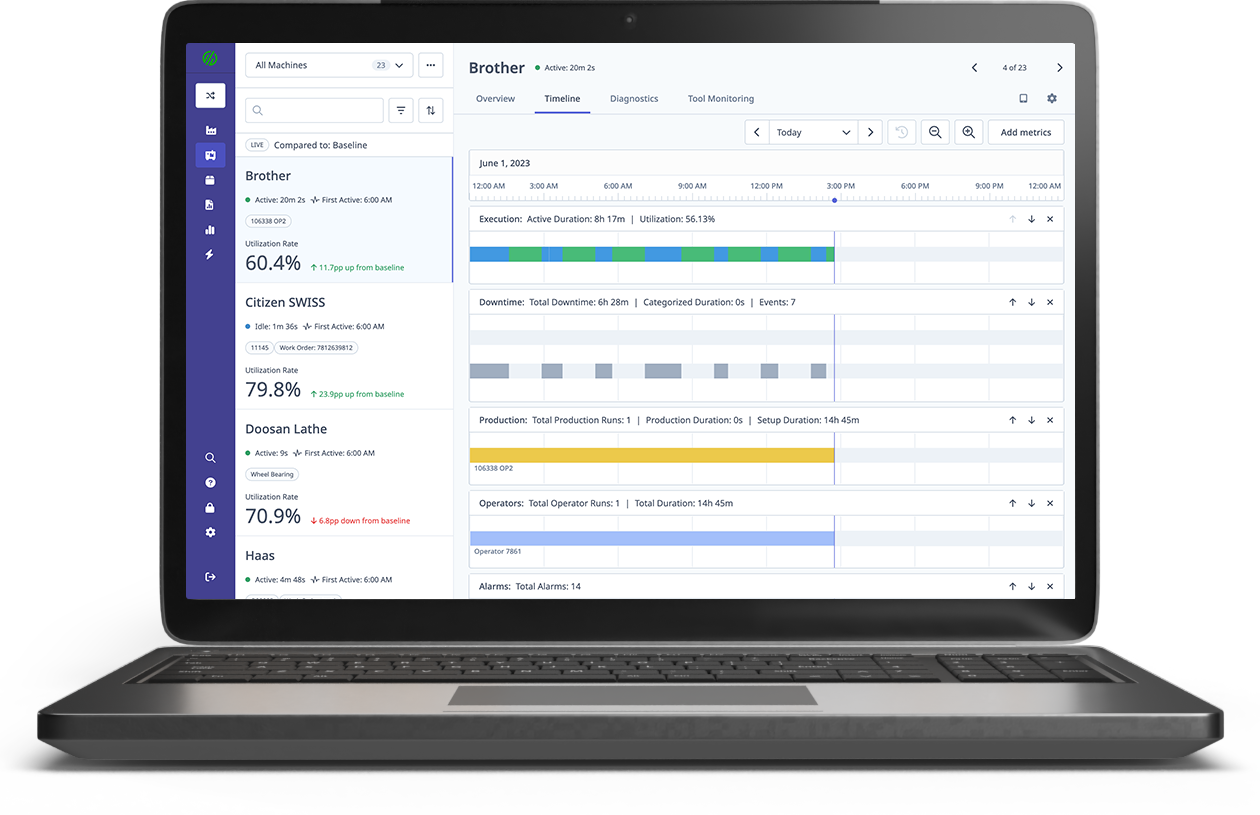

Jordon Schaefer, Manager, Advanced Manufacturing Engineering

In one year, SilencerCo was able to realize remarkable improvements in both the efficiency and profitability of their production leveraging MachinoX Pro.

Want to see MachinoX Pro in action first? BOOK A FREE TRIAL