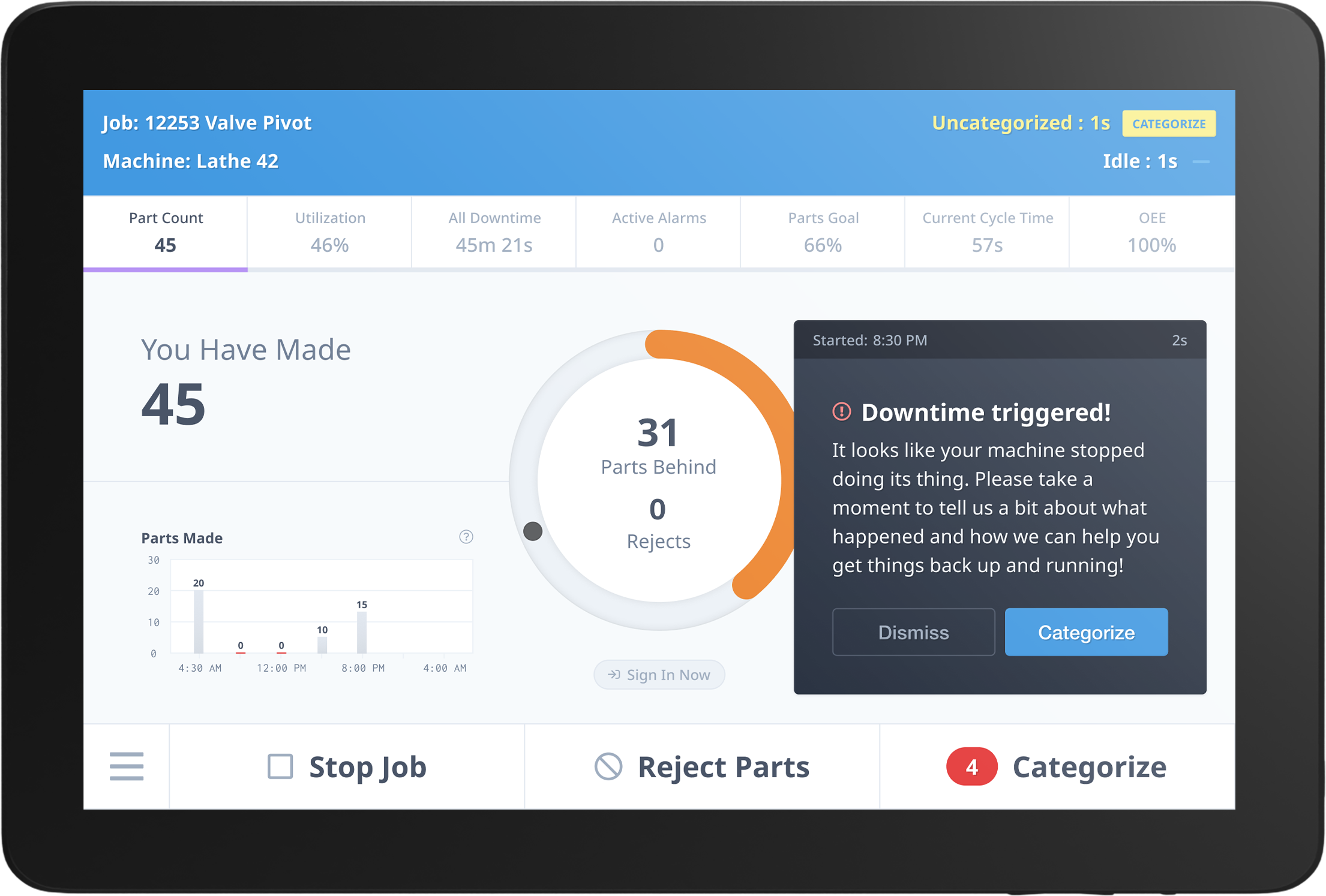

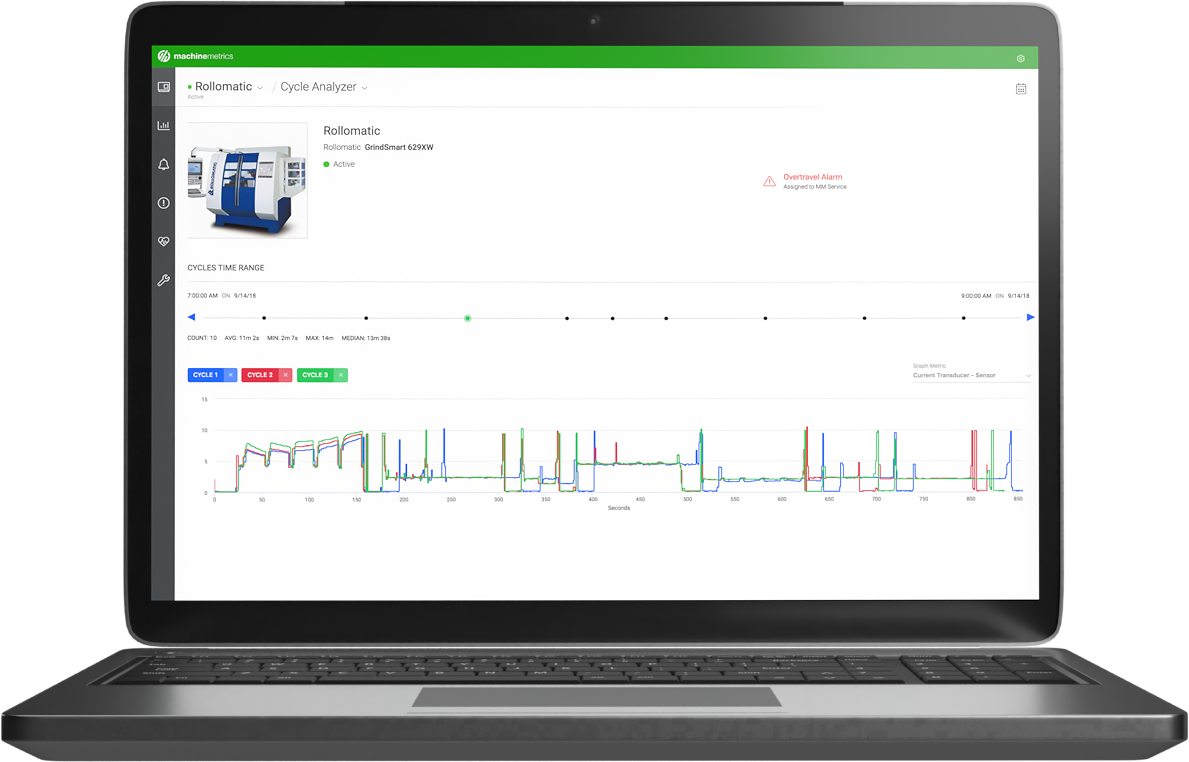

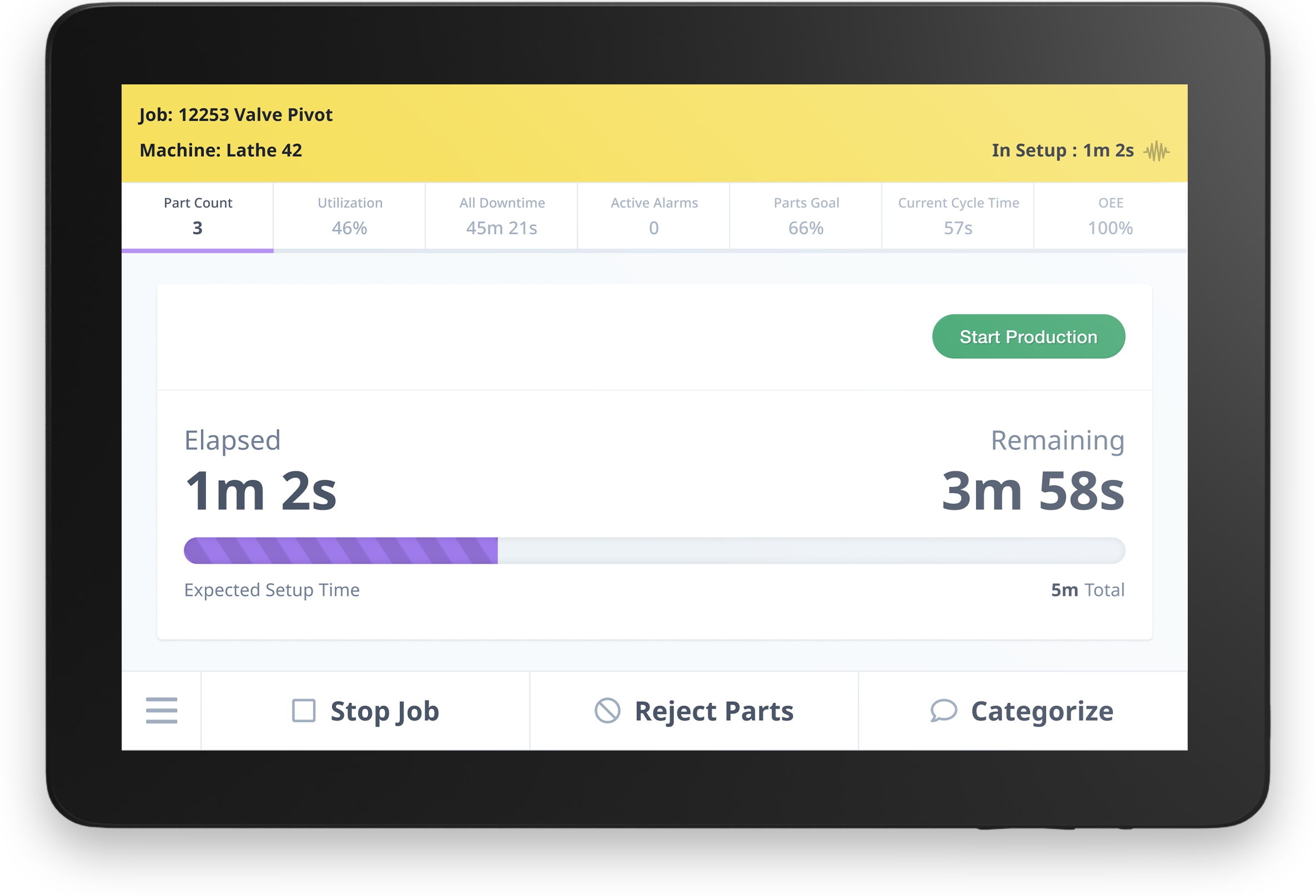

Our robust, user-friendly, and adaptable production and process optimization applications are guided by analytics, ensuring your team is well-informed about what actions to take, their timing, and ways to enhance their performance.

Industrial IoT Platform for Machines

Plug-and-play, simple to use, and easy to scale.

Eliminates time-consuming data tag mapping.

Out-of-the-box apps with no initial development required.

Easily integrates machine data across your digital factory

Provides necessary context to enable data actionability

Gary Bruner, President of Carolina Precision Manufacturing

Learn how MachinoX Pro helped Carolina Precision Manufacturing save over $1.5 million in their first year of machine monitoring.

Want to see MachinoX Pro in action first? BOOK A FREE TRIAL