Your one-stop shop for high-quality factory and industry

products [for designed to grow line]

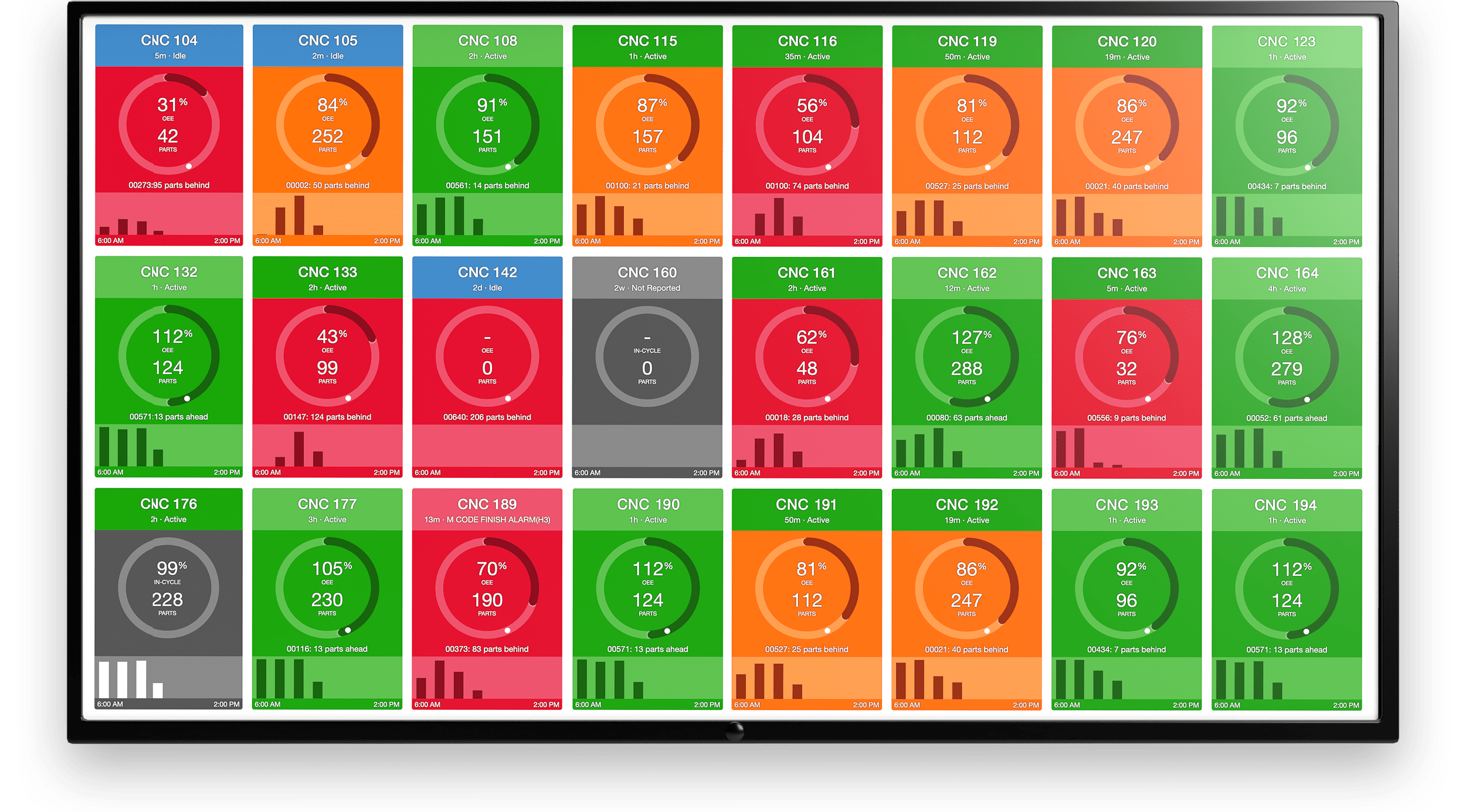

The OEE Details Display is a cutting-edge industrial tool designed to optimise operational efficiency, enhance productivity, and streamline manufacturing processes. It provides real-time insights into Overall Equipment Effectiveness (OEE) metrics, enabling businesses to make data-driven decisions that improve equipment performance and ultimately their bottom line.

Real-time Operational Efficiency Insights at Your Fingertips

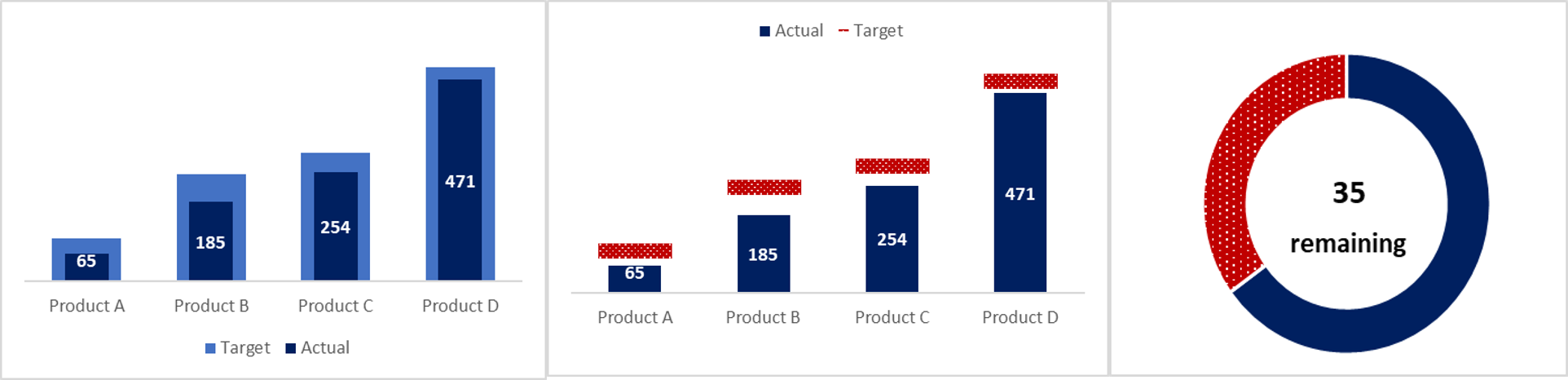

Strategic Insights for Goal Achievement

Key Aspects of Production Downtime Monitoring

Every package offers dedicated customer assistance, limitless remote tech support, seamless onboarding, comprehensive product training, and a dedicated support contact.

The OEE Details Display is a cutting-edge industrial tool designed to optimise operational efficiency, enhance productivity, and streamline manufacturing processes. It provides real-time insights into OEE metrics, enabling businesses to make data-driven decisions, reduce downtime, and maximise production output.

Introducing our Production Counter Displays – the ultimate solution for efficient production tracking and management. Designed for industrial environments, these displays provide real-time production data at a glance, ensuring your operations run smoothly and effectively.

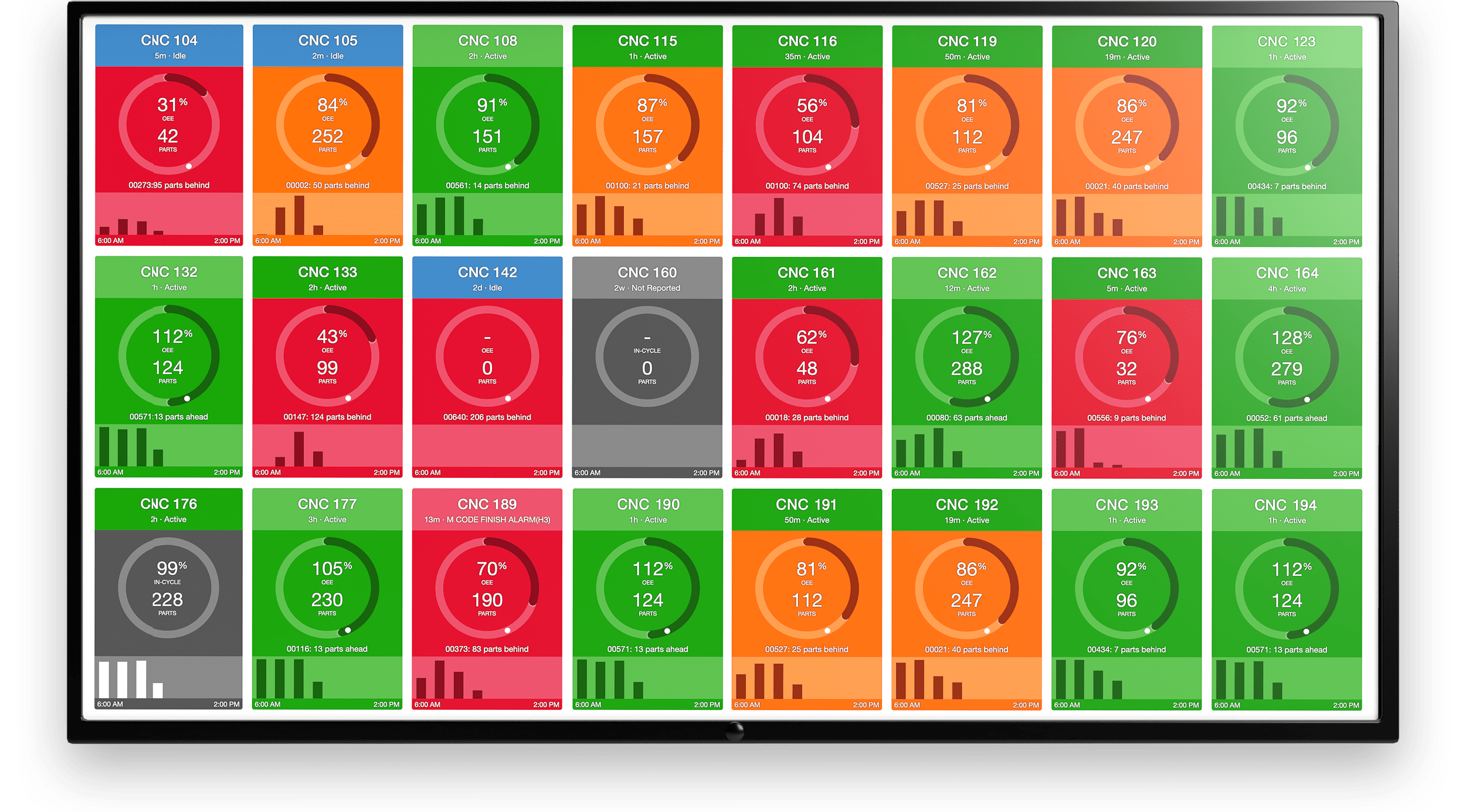

Production Downtime Monitoring is a cutting-edge solution designed to optimize manufacturing processes by minimizing downtime, ensuring maximum productivity, and boosting overall efficiency. This innovative system offers real-time insights into production line disruptions, allowing businesses to make informed decisions and maintain seamless operations.

Track production downtime in real-time, enabling instant response to issues.

Generate detailed reports and analytics to identify patterns and trends in downtime.

Receive instant notifications via email or mobile alerts when downtime events occur.