Production Downtime Monitoring is a cutting-edge solution designed to optimize manufacturing processes by minimizing downtime, ensuring maximum productivity, and boosting overall efficiency. This innovative system offers real-time insights into production line disruptions, allowing businesses to make informed decisions and maintain seamless operations.

Instantly track production numbers, helping you stay updated on output metrics.

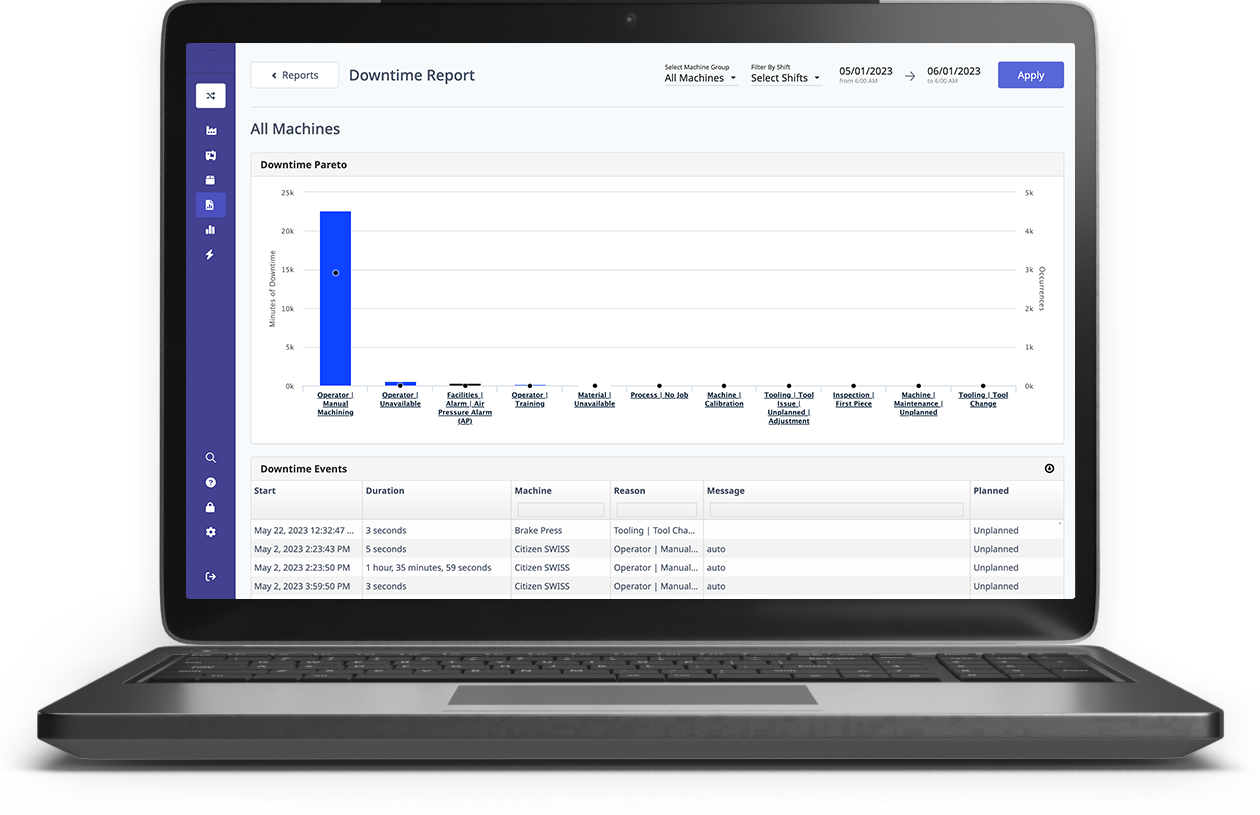

Generate detailed reports and analytics to identify patterns and trends in downtime.

Receive instant notifications via email or mobile alerts when downtime events occur.

Intuitive dashboard for easy navigation and quick access to essential information.

Tailor the system to your specific production environment with customizable settings.

Analyze historical downtime data to prevent recurring issues and optimize processes.

Compatible with various manufacturing equipment and systems.

Supports IoT devices, sensors, and PLCs for real-time data acquisition.

Scales effortlessly to accommodate growing production needs.

Ensures data integrity and confidentiality with advanced encryption protocols

Hosted on secure cloud servers for accessibility and data backup.

Offers API for seamless integration with third-party applications.

Pinpoint the causes of downtime, such as equipment failures or maintenance issues, for quick resolution.

Optimize production schedules based on historical downtime data, ensuring efficient resource allocation.

Schedule preventive maintenance activities during planned downtime to minimize unplanned disruptions.

Monitor packaging lines, minimizing downtime and maximizing packaging efficiency.

Identify production bottlenecks and quality-related issues contributing to downtime, enabling process enhancements

Share downtime data with suppliers to improve the supply chain and reduce delays in raw material deliveries

Monitor production downtime related to regulatory compliance, ensuring adherence to industry standards.