MachinoX Pro monitors OEE, machine utilization, and downtime for maximum production efficiency and deep operational insights. No manual data entry required.

Unlocking accurate, real-time production data is really hard. Most manufacturers manually collect data from their shop floors and enter it into management systems. This is time-intensive and leads to delayed, inaccurate production data that is not actionable.

This results in massive inefficiencies, from an inability to drive process improvements or justify capital expenditures, to unexpected machine downtime and production losses.

Continuous improvement in manufacturing starts with capturing data from your operations - specifically your machine assets. MachinoX Pro has automated machine data collection to deliver data-driven insights in a matter of minutes.

The data captured from equipment drives immediate insights for both people and systems, enabling them to make better, faster decisions as well as drive automation.

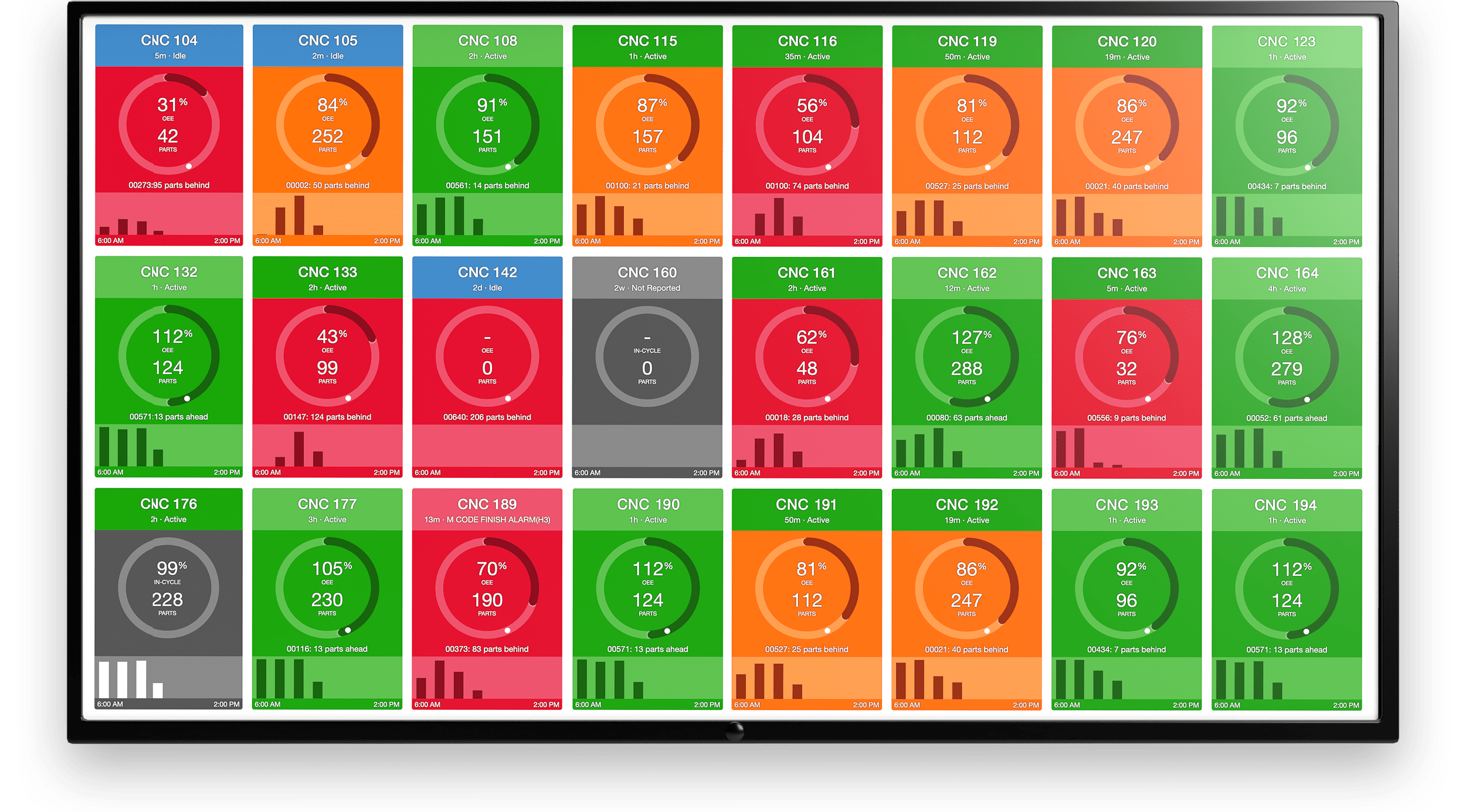

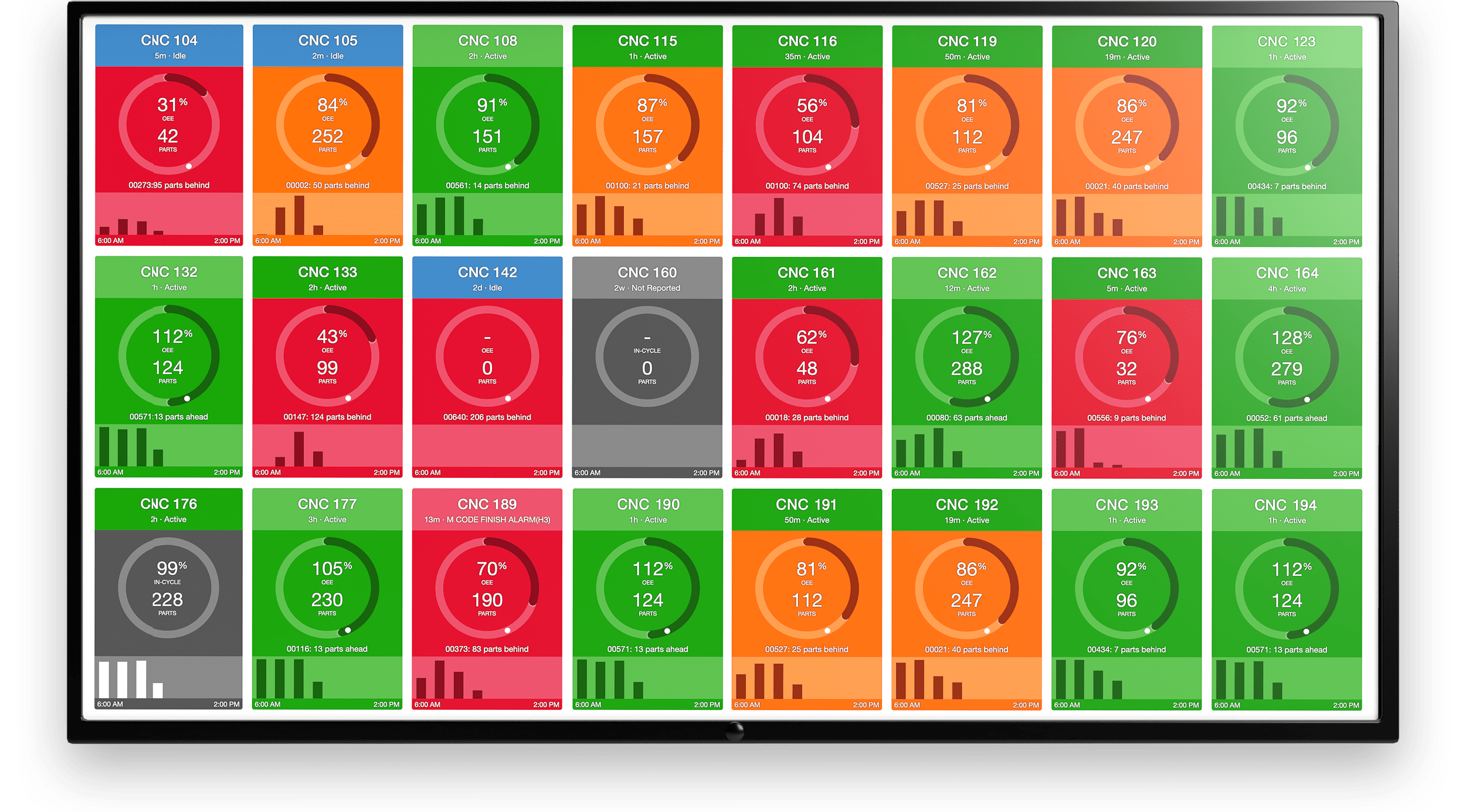

PRODUCTION MONITORING PLATFORM

Collect data from any machine by connecting the MachinoX Pro Edge to the ethernet port of the control. Software on the edge processes data from the machine in real-time and streams the data securely to the

MachinoX Pro Cloud

View and manage the status of your machine assets from anywhere. Easily scale across all equipment.

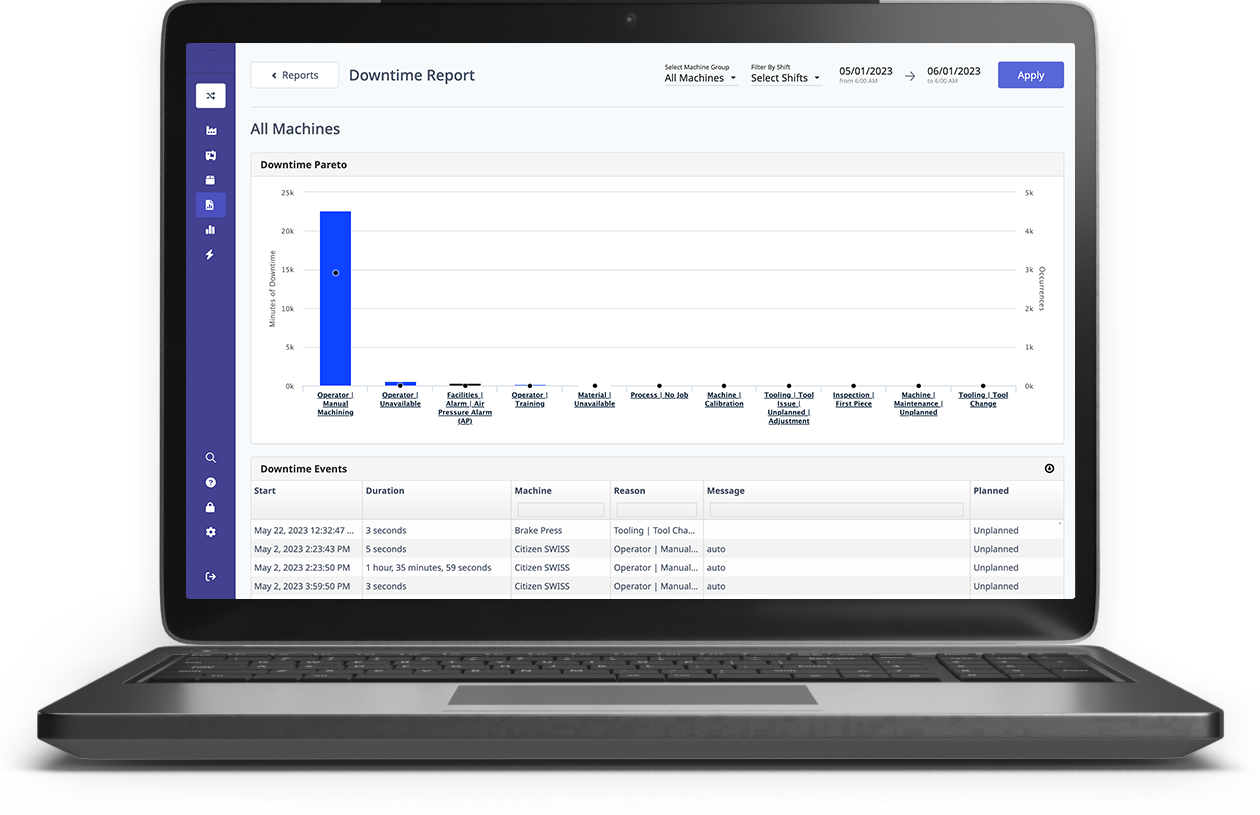

Visualize machine utilization by hour, shift, day, week, and month to analyze trends and uncover hidden capacity across the shop floor.

Drive a condition-based maintenance program using real-time machine diagnostics. Push the data into a CMMS to automatically create work orders.

Streamline production monitoring through automation

Enable operators to achieve production targets by providing real-time insights into performance and promptly identifying production challenges.

MachinoX Pro Cloud

Want to see MachinoX Pro in action first? BOOK A FREE TRIAL