Condition monitoring is the process of regularly assessing the health and performance of your machinery to detect issues early and prevent costly breakdowns. It helps ensure uninterrupted operations and reduces maintenance costs.

Unlock Peak Performance with Robato Systems' Condition Monitoring Services

- Implement real-time machine condition monitoring.

- Deploy it within minutes.

- Utilize machine data to extend equipment longevity.

- Ensure healthier equipment operation.

- Establish connections.

- Gather machine condition data.

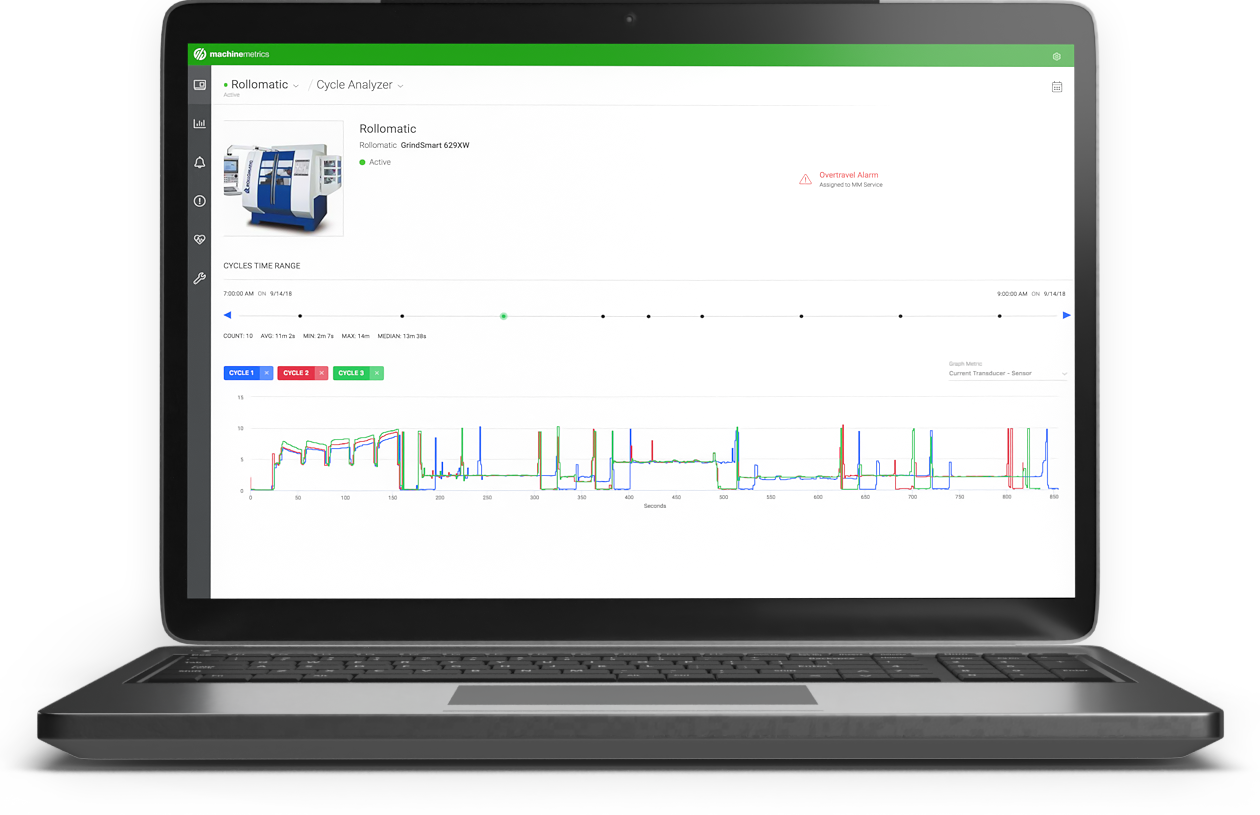

- Visualise data from any factory floor equipment.

- Diagnose problems and Analyze PMC and diagnostic control data.

- Utilise real-time visualisations.

- Leverage analytics for machine health assessment.

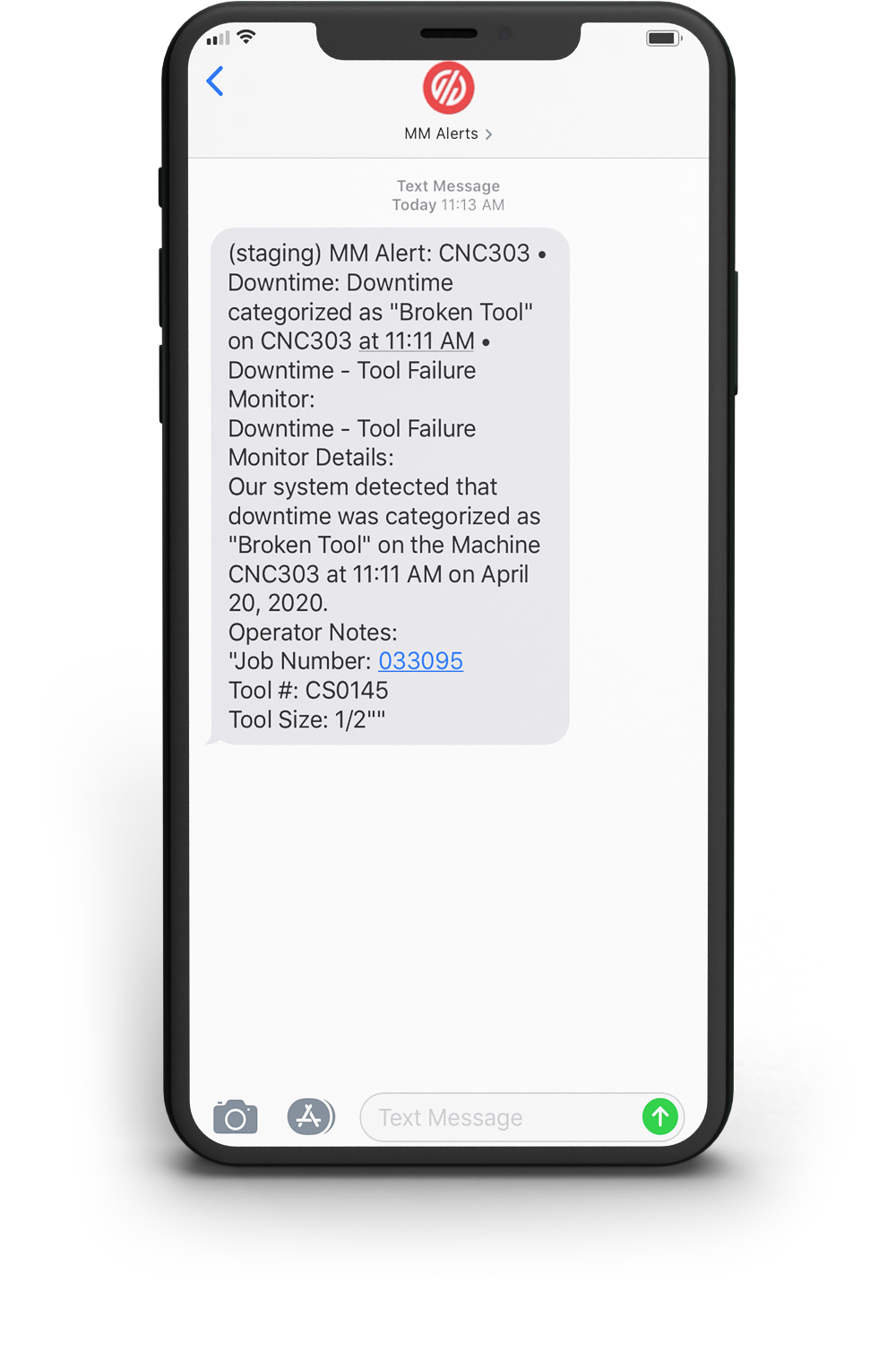

- Ensure machine uptime and Respond to machine alarms.

- Receive optimised maintenance alerts.

- Alerts triggered by critical KPIs and monitors condition thresholds.

Inadequate machine health data results in suboptimal operation

Reliance on calendar-based preventive maintenance plans proves inefficient and frequently results in either excessive, costly maintenance or insufficient maintenance that leads to machine failures and downtime.

Leverage real-time condition data for optimization purposes

- Monitor real-time machine diagnostics.

- Monitor machine conditions.

- Schedule maintenance at the ideal moment.

- Prevent unforeseen downtime and machine failures.

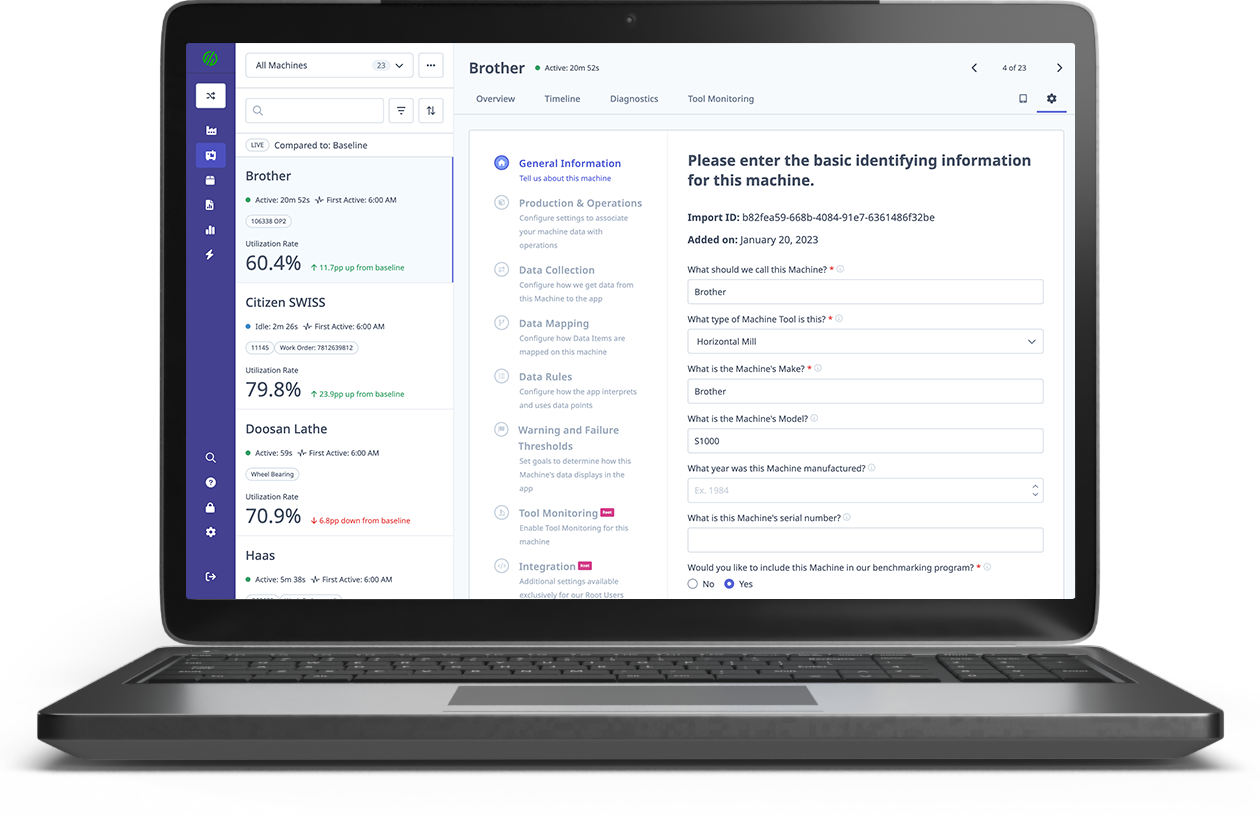

- Establish connections with any asset.

- Connect via the Andon Edge, linked to the control and/or sensors' Ethernet port.

- Real-time data processing at the edge.

- Securely stream machine data to the Andon cloud.

- Securely stream machine data to the Andon cloud.

- Automatic mapping of available data points.

- Collection of data points such as Internal Sensors, Machine Status, Modes, Alarms, Overrides, Load, Speeds, Feeds, and more.

- Standardization of collected data.

- Integrate external sensors seamlessly.

- Establish connections with older equipment using digital and analog IO.

- Configure and manage these connections remotely via a web interface.

- Automate the capture and transformation of machine data.

- Contextualise the data efficiently.

- Deliver consumable machine data and insights within minutes.

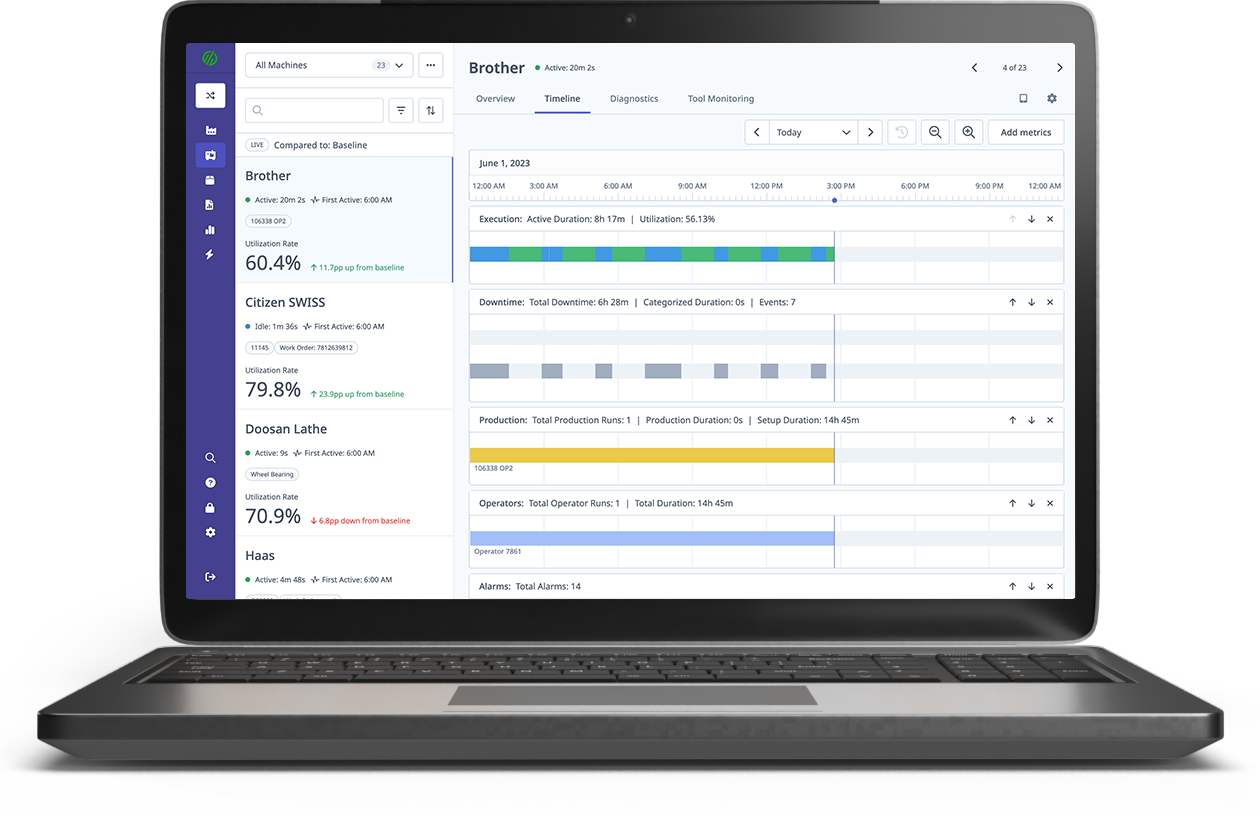

- Diagnose issues using real-time insights.

- Analyse machine control and sensor data.

- Prevent unplanned downtime.

- Visualise previously hidden machine condition aspects in real-time.

- Access and export real-time machine data and alarms as time-series data and charts.

- Aid in problem diagnosis and resolution.

- Monitor the status and health of machine assets.

- Export real-time machine data and alarms as time-series data and charts.

- Utilize this data for problem diagnosis and resolution.

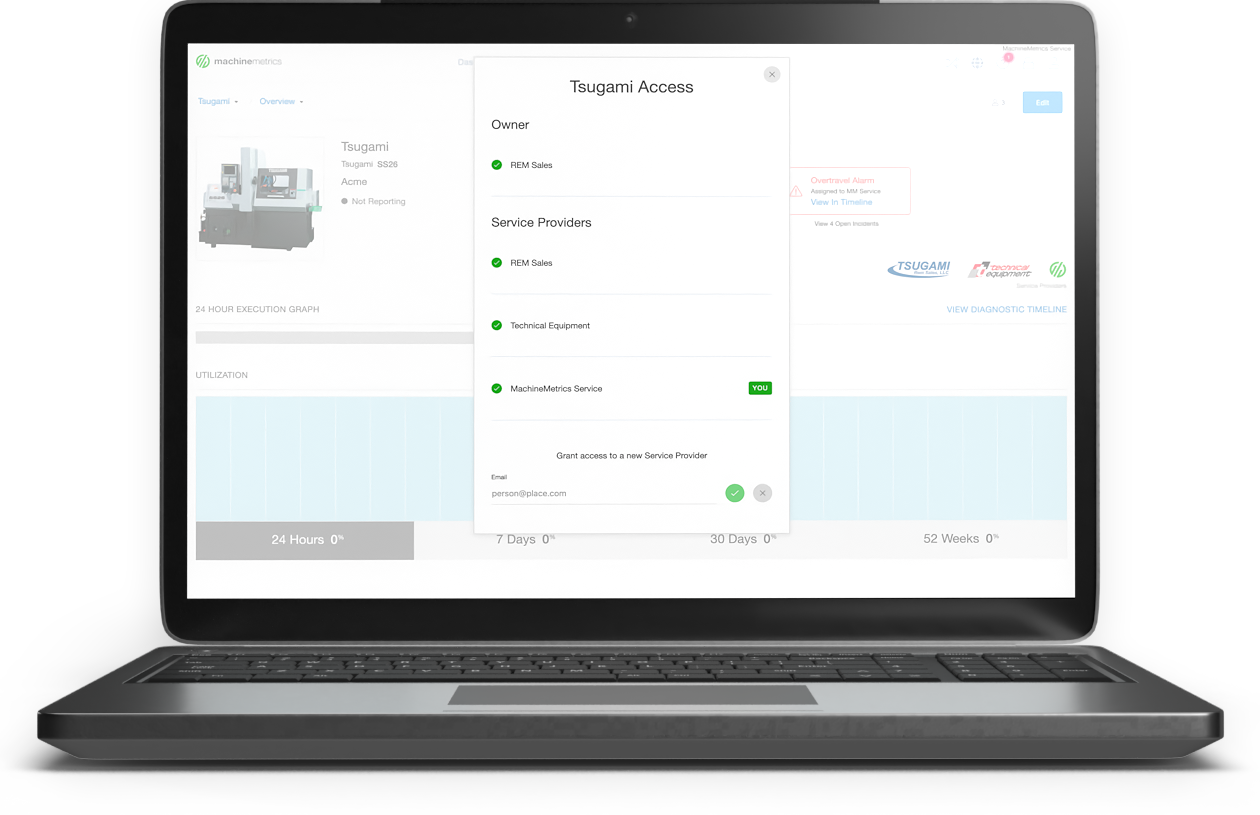

- Share machine data instantly with your service provider.

- Enable remote service for faster machine recovery.

- Expedite the process of getting your machines back online.

- Timely alerts to the appropriate personnel and comprehensive audit trail for tracking purposes.

- Incident tracking within a structured workflow.

- Capability for reassignment and Resolution management.

.png)

- Anticipate equipment failures and offer solutions proactively.

- Customise preventive maintenance schedules to match operational demands.

- Gather and assess the essential data for diagnostic and predictive maintenance.

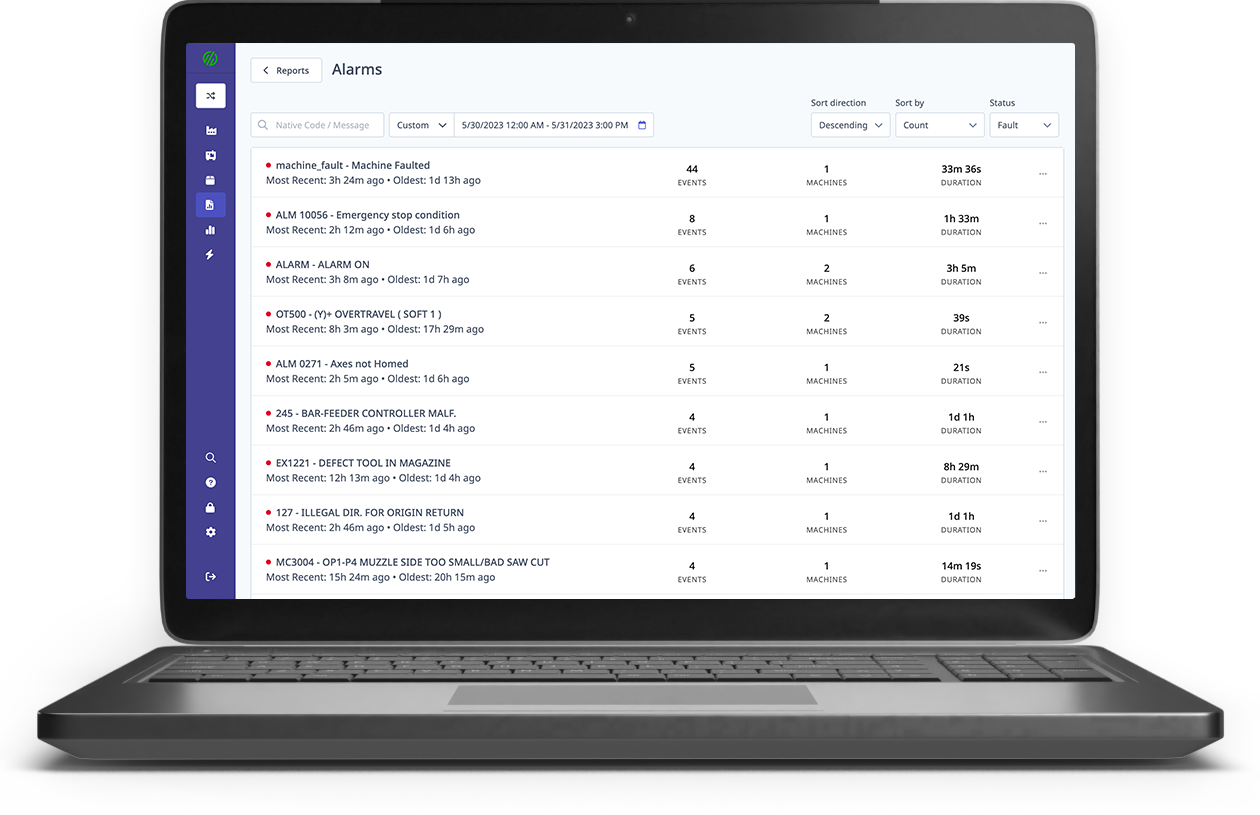

- Identify alarms responsible for significant downtime.

- Access comprehensive alarm histories for individual machines.

- Obtain a summarized overview of alarms spanning your entire shop floor.

- Establish workflows to trigger preventive maintenance events.

- Connect these workflows to your Computerised Maintenance Management System (CMMS).

- Initiate maintenance based on calendar time, usage time, or predefined machine condition limits.

- Enhance predictive analytics with high-frequency machine data.

- Utilise this data to diagnose and predict a wide range of equipment failures.

- Prevent various types of breakdowns in your manufacturing equipment.

The Unique Andon Advantage

- Plug-and-play simplicity

- Scalability made easy

- Seamless connections

- No need for time-consuming data tag mapping

- Immediate data utilisation

- Immediate Value and quick ROI

- Connects effortlessly with various machine data sources

- Enhances data intelligence

- Out-of-the-box apps, no initial development necessary

- Provides essential context for actionable data

- Industry-specific knowledge for optimization

Frequently asked questions

Condition monitoring services are versatile and can be applied to various types of machinery, including industrial equipment, manufacturing machines, HVAC systems, and more.

Condition monitoring services provide benefits such as increased machine uptime, reduced maintenance costs, improved safety, and enhanced overall equipment efficiency (OEE).

Yes, in most cases, sensors or monitoring equipment need to be installed on your machinery to collect relevant data. These sensors are non-invasive and can be retrofitted to existing machines.

MachinoX Pro Blog

Request A Demo

Book a tailored demonstration of MachinoX Pro that aligns with your specific manufacturing needs.

Book A Demo Now