Machine monitoring involves real-time data collection and analysis of equipment performance. It is crucial for predictive maintenance as it helps detect issues before they cause costly breakdowns, reducing downtime and maintenance costs.

Elevate Your Operations with Robato Systems' Predictive Maintenance Services

- Enhance predictive analytics with high-frequency machine data.

- Diagnose and predict equipment failures with precision.

- Prevent breakdowns in manufacturing equipment.

- No need for additional sensors.

connections with machines

- Establish connections and gather high-frequency data.

- Visualise data from shop floor equipment.

- Utilise transformed data.

- Develop predictive algorithms and workflows promptly.

- Provide pre-built or customised applications on the Edge.

- Prevent issues proactively.

Unexpected downtime comes at a significant cost

- Acquiring, parsing, and cleaning data for factory analysis is a messy and tedious task.

- Tool breakage can result in significant costs.

- Damaged tools may produce seemingly compliant parts that are ultimately scrapped.

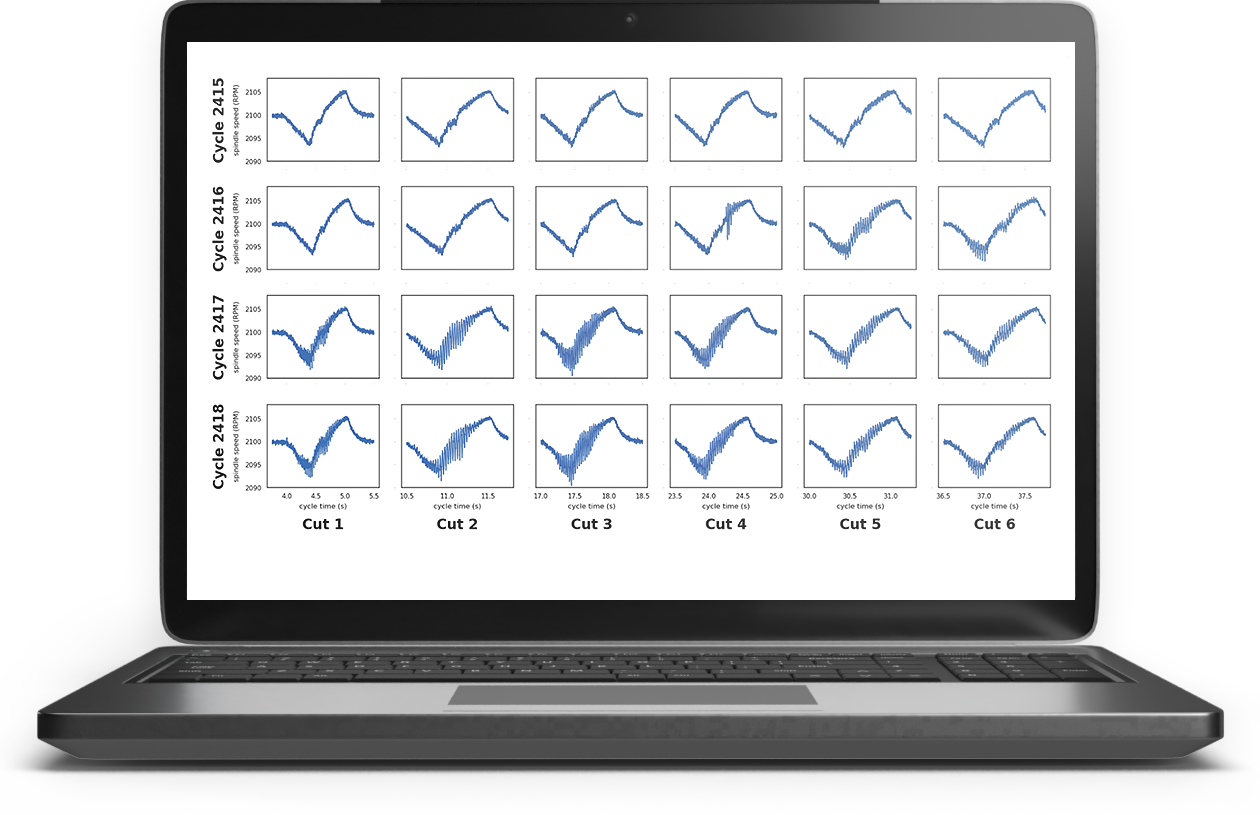

- Subtle variations in machine load, torque, acceleration, and spindle speed can lead to parts being produced outside of necessary tolerances.

- All of these factors consume both time and finances.

Anticipate Issues — Prevent Downtime in Advance

- Collect high-frequency machine data in real-time.

- Utilise this data for diagnosis and prediction.

- Proactively prevent various types of failures.

- Andon connects to thousands of machine tools.

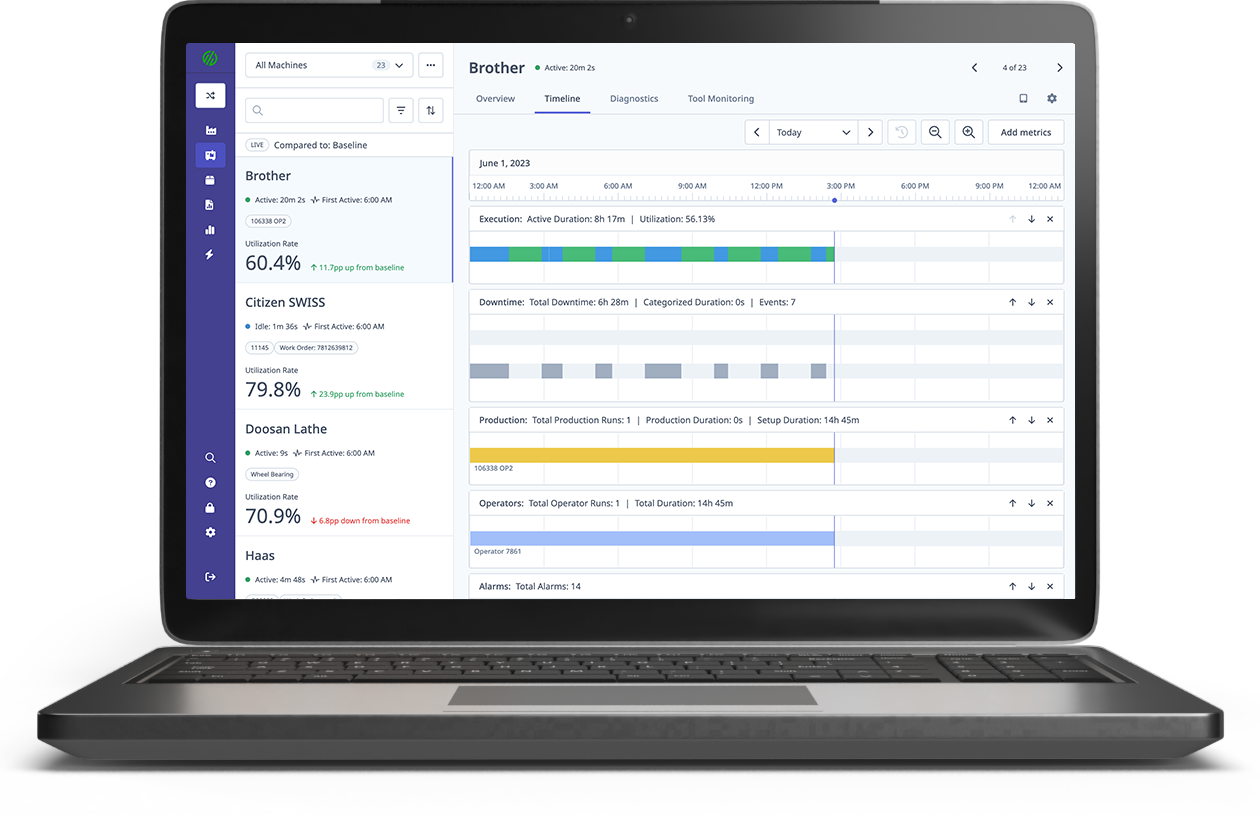

- Data scientists develop algorithms for predicting quality defects and tool life extension.

- Operators label data via the operator interface when tool failures or quality defects happen.

- ML/AI algorithms analyse patterns from the extensive data collected from each machine.

- The algorithms detect issues before they reoccur and halt the machine to prevent failure.

- Identify the onset of stress fractures in tools.

- Alert the operator when such fractures are detected.

- Promptly remove affected tools from operation to prevent failure or breakage.

- Identify tool wear from material variations, environmental factors, and cutting conditions.

- Extend tool lifespan by optimising tool usage.

- Maximise tool performance for prolonged use.

- Prevent compromised tools from affecting performance.

- Enhance finishing quality and prevent incomplete cuts.

- Implement tool chatter detection to address these issues.

- Empower your data science team to expedite predictive analytics.

- Utilise data directly as inputs for time-series or machine learning models.

- Employ tools like Spark, R, and Python to create algorithms for failure detection.

- Deploy and oversee custom algorithms for edge data analysis.

- Trigger alerts to factory workers or preempt equipment failure using these algorithms.

- Utilise high-frequency data from machine control or sensors.

- Employ this data as inputs for time-series or machine learning models.

- Implement and oversee custom algorithms.

- Deploy them to Andon Edge devices and detect potential failures using these algorithms.

- Enable processing and analysis at the source.

When an algorithm activates:

- Send operator alerts/notifications.

- Inform factory workers of required actions.

- Automatically initiate a feed-hold to halt machines before equipment failure occurs.

What Sets Andon Apart

- Plug-and-play simplicity.

- Scalable and user-friendly.

- Seamless connections.

- Eliminates the need for time-consuming data tag mapping.

- Immediate data usability.

- Pre-built applications with no initial development needed.

- Quick value realisation.

- Effortlessly integrates machine data throughout your digital factory.

- Enhances data intelligence.

- Offers essential context to make data actionable.

- Specialised in manufacturing verticals.

Frequently asked questions

Our services are versatile and can be applied to various industrial equipment, including manufacturing machines, HVAC systems, conveyor belts, and more.

We install sensors on your equipment to collect data on factors like temperature, vibration, and usage patterns. Our software then analyzes this data to predict when maintenance is needed.

Our system is designed to be compatible with a wide range of equipment and can integrate with most existing industrial control systems and sensors.

MachinoX Pro Blog

Request A Demo

Book a tailored demonstration of MachinoX Pro that aligns with your specific manufacturing needs.

Book A Demo Now